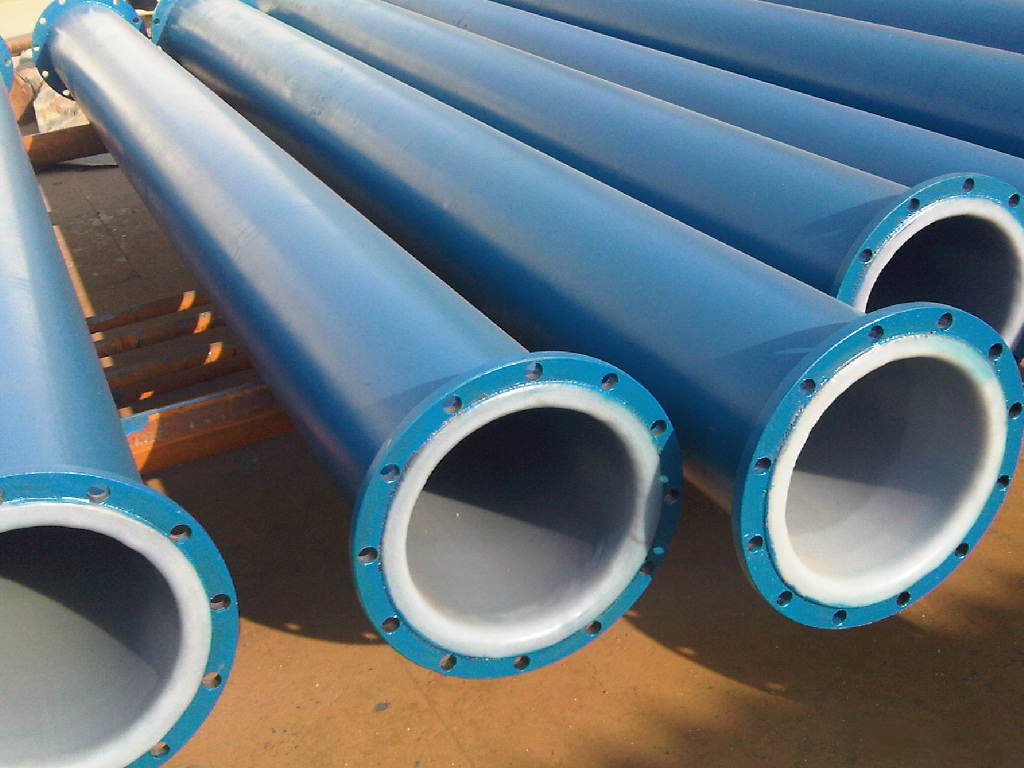

Fluorine-lined pipes and PO-lined pipes

time:2015-12-21 views:384

Product Type: Fluorine-lined Pipe, PO-lined Pipe

Main features: Flanges can be forged or determined by contract according to national standards such as HG, GB, JB, ANSI, JIS, BS, DIN and so on. Flanges with plate and neck are recommended for sealing surface processing. The sealing surface is of plane sealing type. In order to facilitate pipeline installation, the flat welded ring movable flange can be provided for users.

Fluoroplastic Pipeline

1. Requirements for Selection of Steel Pipes and Flanges for PTFE Lined Pipelines and Pipe Fittings

1. Fluoroplastics pipes are made of national Peugeot non-encounter steel pipes. Because of the technological requirements, the effective diameter of the pipes lining is smaller than the nominal diameter of the pipes. The designer and users determine the diameter of the pipes after carrying out the necessary effective flow standards.

2. Flanges can be forged or determined by contract according to national standards such as HG, GB, JB, ANSI, JIS, BS, DIN and so on. Flanges with plate and neck are recommended for sealing surface processing. The sealing surface is of plane sealing type. In order to facilitate pipeline installation, the flat welded ring movable flange can be provided for users.

II. Test, Inspection and Application Scope of PTFE Lining Layer

1. Fluoroplastics pipes and fittings are tested under 1.5 times design pressure.

2. Where PTFE lining is involved, after hydrostatic test, 100% of the lining is tested for integrity, and the leak point is tested by EDM.

3. Scope of Use

A. Use temperature - 20-200 C B. Use pressure < 2.5 Mpa C. Allow negative pressure to overwhelm most Dn < 250 to - 0.09 Mpa, Dn > 250 to - 0.08 Mpa

Rolling lining PE (PO) fluoroplastics pipes and pipe fittings:

1. Choose imported high-performance raw materials and reasonable formula, adopt advanced hot rolling lining technology, combine plastic and steel matrix by hot melting. The whole anticorrosive lining has the following characteristics:

A. No lap joint, impact resistance, aging resistance, positive and negative pressure resistance. Smooth surface, any shape of steel can be lined inside and outside.

B. Universal temperature: - 60-100 C

C. General Pressure: - 0.07 Mpa - --- 2.5 Mpa

2. Scope of application: Widely used in chemical industry, electric power, smelting, pharmaceutical, food, environmental protection, electroplating and other fields. Except more than 95% sulphuric acid and concentrated sulphuric acid, inorganic acids, organic acids, alkali salts of various concentrations are stable. They are substituted for rubber, enamel, stainless steel, fiberglass reinforced plastics, plastic sheet (pipe) linings in the temperature range of - 20 ~100%. Ideal anticorrosive material.

Pre-use maintenance and precautions:

1. It is forbidden to store in open air for a long time, avoid sunshine, rain, violent collision and multi-layer stacking of heavy objects.

2. The sealing surface must not be scraped, cut, scratched, scratched or collided with hard objects.

3. It is absolutely forbidden to weld, wind-cut, fire-bake on the steel body of the lined pipe fittings and fittings. It should be more than 1 meter apart from the heat source.