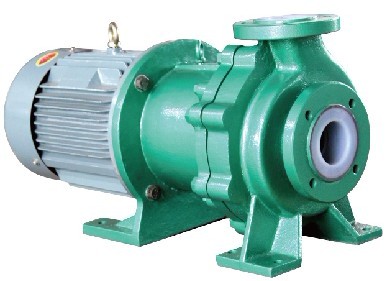

IMC Fluoroplastic Magnetic Pump

time:2015-12-19 views:449

IMC Fluoroplastic Magnetic Pump

Product model: IMC magnetic pump

Main features: working temperature: - 20 ~100 C

Flow: 6m3/h~120m3/h

Head: 15m~40m

Product Profile

_IMC series products are high-power and high-lift magnetic drive pumps developed by the company based on 20 years'experience in manufacturing magnetic pumps. Their appearance and installation dimensions are designed and manufactured in accordance with ISO international standards. The overall structure adopts the back-pull type of direct motor connection (our company's patent). They are supported by intermediate brackets, compact in structure, convenient in disassembly and maintenance. The magnet steel used to transfer torque adopts advanced rare earth permanent magnet --"Nd-Fe-B" to make internal and external magnets. The isolation sleeve combination made of new non-metallic material lined F46 has high strength mechanical properties, eliminates the eddy current loss of common magnetic pump, and improves the efficiency of the whole machine. It can convey high concentration and high density corrosive medium over 1.84 t/m3. The main components are steel lining F46. The pump body has high strength and can resist all strong acid and alkali corrosion. It is suitable for transporting inflammable, explosive, toxic, volatile and high specific gravity chemical media. Now it has been put into the market in batches, replacing imported magnetic pumps in many projects, and has been widely praised by users.

_working conditions

_Applicable temperature: - 20 ~100 C.

_Product Usage

This product is widely used in petrochemical industry, acid and alkali making, non-ferrous metal smelting, pickling process in automobile manufacturing, rare earth separation, pesticides, dyes, pharmaceuticals, papermaking, electroplating, radio and other industries to transport acid, alkali, oil, rare precious solutions, poisonous liquids, volatile liquids, especially flammable, explosive. Transportation of high specific gravity liquid.

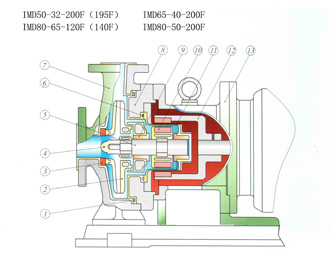

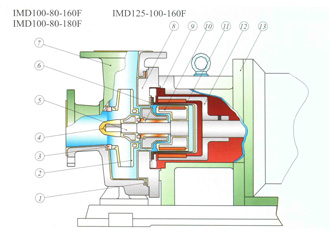

_Product Structure Diagram:

|

Model |

Flow (m3/h) |

Head (m) |

Motor power (kw) |

Cavitation margin (m) |

Import/export |

Speed (r/min) |

Efficiency (%) |

Weight

(Kg)

|

|

IMD40-25-120F |

6 |

17 |

3 |

3 |

40x25 |

2900 |

32 |

|

|

IMD40-25-130F |

6 |

20 |

3 |

3 |

40x25 |

2900 |

35 |

|

|

IMD40-25-140F |

6 |

26 |

3 |

3 |

40x25 |

2900 |

36 |

|

|

IMD40-25-150F |

6 |

30 |

3 |

3 |

40x25 |

2900 |

37 |

|

|

IMD40-25-160F |

6 |

35 |

3 |

3 |

40x25 |

2900 |

48 |

|

|

IMD40-25-170F |

6 |

39 |

3 |

3 |

40x25 |

2900 |

32 |

|

|

IMD40-25-230F |

6 |

60 |

7.5 |

3 |

40x25 |

2900 |

25 |

|

|

IMD50-40-140F |

15 |

28 |

5.5 |

3.2 |

50x40 |

2900 |

41 |

|

|

IMD50-40-150F |

15 |

32 |

5.5 |

3.2 |

50x40 |

2900 |

42 |

|

|

IMD50-40-160F |

15 |

39 |

5.5 |

3.2 |

50x40 |

2900 |

46 |

|

|

IMD50-32-200F |

15 |

50 |

7.5 |

3.2 |

50x40 |

2900 |

35 |

|

|

IMD65-50-120F |

30 |

17 |

5.5 |

3.5 |

65x50 |

2900 |

60 |

|

|

IMD65-50-130F |

30 |

21 |

5.5 |

3.5 |

65x50 |

2900 |

65 |

|

|

IMD65-50-160F |

30 |

33 |

5.5 |

3.5 |

65x50 |

2900 |

58 |

|

|

IMD65-40-200F |

30 |

50 |

11 |

3.5 |

65x40 |

2900 |

50 |

|

|

IMD80-65-120F |

60 |

20 |

7.5 |

3.5 |

80x65 |

2900 |

70 |

|

|

IMD80-65-140F |

60 |

25 |

7.5 |

3.5 |

80x65 |

2900 |

68 |

|

|

IMD80-65-160F |

60 |

32 |

11 |

3.5 |

80x65 |

2900 |

65 |

|

|

IMD80-50-200F |

60 |

50 |

15 |

3.5 |

80x50 |

2900 |

60 |

|

|

IMD80-50-250F |

50 |

80 |

30 |

3.5 |

80*50 |

2900 |

52 |

|

|

IMD100-80-160F |

100 |

32 |

18.5 |

3.5 |

100x80 |

2900 |

68 |

|

|

IMD100-80-180F |

100 |

40 |

30 |

5 |

100x80 |

2900 |

70 |

|

|

IMD100-80-315F |

50 |

32 |

11 |

4.5 |

100*80 |

1450 |

58 |

|

|

IMD100-65-200F |

100 |

50 |

30 |

4 |

100x65 |

2900 |

65 |

|

|

IMD125-100-160F |

120 |

20 |

30 |

4.5 |

125x100 |

2900 |

70 |

|

|

IMD125-100-200F |

200 |

32 |

37 |

5.0 |

125x100 |

2900 |

65 |

|

|

IMD200-150-250 |

400 |

20 |

45 |

3.2 |

200x150 |

1450 |

60 |

|

- Prev:IMD Fluoroplastic Magnetic Drive Pump

- Next:无