NMQW Jacket Thermal Insulation Magnetic Pump

time:2018-12-17 views:464

Product model: NMQW jacket thermal insulation magnetic pump

Main features: It can transport both high-temperature and low-temperature media. This series of magnetic pumps continue the advantages of high-temperature magnetic pumps. For the medium, it must be transported within the specified temperature range.

technical parameter

Caliber: 25-300

Flow: 2 m3/h ~ 1 200 m3/h

Head: 2m ~ 125m

Speed: 2950r/min 1450r/min

Use temperature: - 40oC ~ 450oC

Use pressure: <25 MPa

Summary:

NMQW series jacket thermal insulation magnetic pump (referred to as NMQW magnetic pump) is a thermal insulation magnetic pump developed by our company according to the requirements of users for transporting constant temperature medium. It can transport both high temperature medium and low temperature medium. This series of magnetic pumps continue the advantages of high temperature magnetic pump. In view of the medium must be at the prescribed temperature standard. Inner conveying adopts a unique new type of insulating box structure to keep the original temperature of the medium while conveying, and at the same time it will not produce condensation, crystallization, vaporization and other phenomena due to temperature variation. The corresponding insulating and cooling modes are adopted for the driving part according to different working conditions to ensure that the driving part will not be affected by the temperature of the conveying medium. Impact.

Product introduction:

Using ISO2858 and HG/T 2730 standards, the size of the pump interface conforms to the replacement of IH, CZ and other chemical pumps, with good compatibility, high efficiency and low vibration.

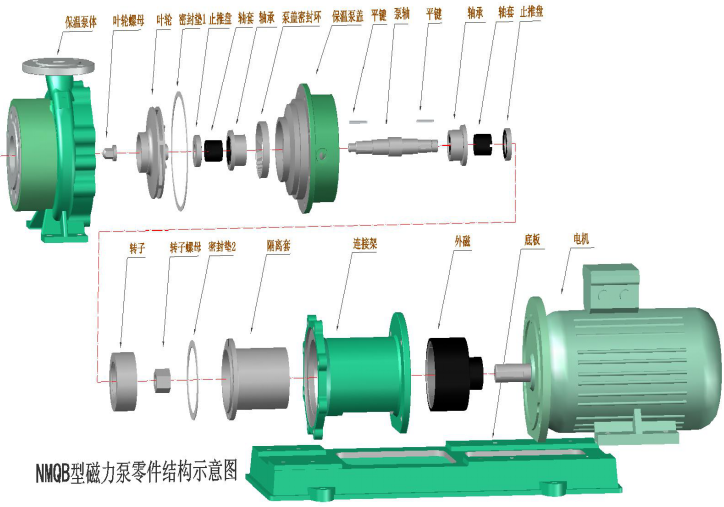

Building block structure is very easy to disassemble and repair, which greatly reduces the professional requirements for maintenance personnel.

The idle protector can be configured according to the user's requirements to avoid the damage caused by idle operation.

It solves the leakage problem of the sealed pump and is also an excellent product to replace the canned pump.

Purpose:

Applicable fields: environmental protection, petrochemical industry, food, biopharmaceutical, electric power, mining metallurgy, textile printing and dyeing, aerospace and other industries, such as refineries, ethylene plants, natural gas processing plants, various chemical plants, pharmaceutical plants, nuclear fuel plants, nuclear power plants, etc.

Applicable technology: Clean, flammable, explosive, volatile, toxic, high temperature and pressure, precious liquid and other occasions requiring no leakage and medium not allowed to seal pollution.

Texture of material:

The flow passage parts of the pump can be made of various corrosion resistant materials such as 304, 304L, 302, 321, 316, 316L, 904, titanium alloy, Hastelloy alloy, nickel-based alloy, etc. according to the working conditions and user requirements. If there are special needs, the unit can design and manufacture according to the working conditions.